The Art and Innovation Behind Custom 3D Puff Embroidery

Explore the evolution and impact of custom 3D puff embroidery in fashion, branding, and apparel. Learn how this bold technique adds depth and character to any design.

Introduction

In the fast-paced world of fashion and branding, uniqueness stands as a pillar of success. Whether you're launching a new streetwear line, outfitting a sports team, or creating promotional merchandise, one technique continues to make a bold impression, custom 3D puff embroidery. Recognized for its raised, tactile quality, this style of embroidery adds dimension and character that flat stitching simply cant achieve.

In this article, well explore what makes 3D puff embroidery so distinct, how its created, its practical applications, and why it has become a go-to solution for companies seeking visual impact.

What is 3D Puff Embroidery?

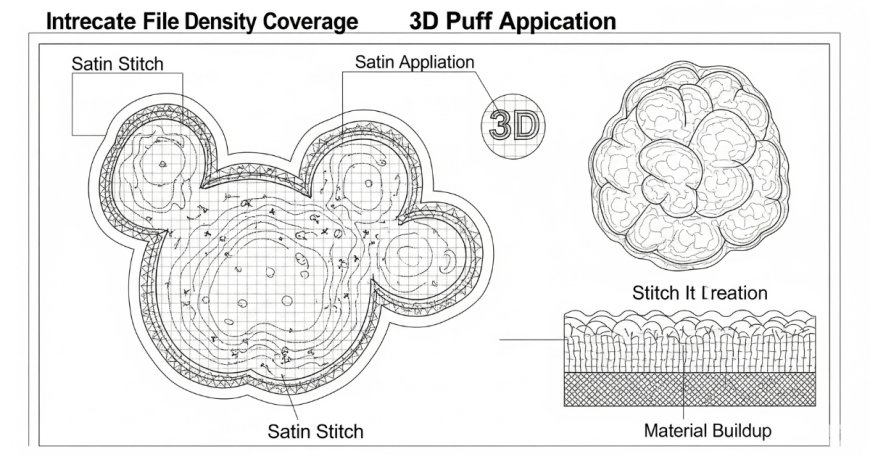

3D puff embroidery is a decorative technique that raises elements of an embroidered design off the surface of the fabric, creating a three-dimensional effect. This is achieved by inserting a layer of foam under the top stitch layer, which is then sewn over with dense satin stitching. The result is a bold, standout design element, often used in logos, monograms, or text.

Custom 3D puff embroidery goes a step further by tailoring every aspect of the design: from font thickness and stitch direction to foam height and thread color, delivering a truly personalized look.

Benefits of Using Custom 3D Puff Embroidery

-

Enhanced Visual Impact

The raised stitching adds texture and dimension, drawing the viewer's eye and making designs pop. -

Durable and Long-lasting

When digitized and executed correctly, puff embroidery is highly durable and resistant to wear and tear, making it ideal for caps, bags, and jackets. -

Professional Appearance

Whether it's a brand logo or creative graphic, puff embroidery adds a polished, high-end aesthetic.

Applications Across Industries

Custom 3D puff embroidery is incredibly versatile and finds use in a variety of settings:

-

Streetwear and Fashion Labels

Caps, hoodies, jackets, and tees are often adorned with puffed logos or branding for visual distinction. -

Corporate Apparel

Many businesses use this style for promotional gear and staff uniforms to reflect a high-quality image. -

Sports and Team Gear

Jerseys, team caps, and accessories use puff embroidery for numbers, initials, or team logos that stand out. -

Limited-Edition Merchandise

Perfect for brand collaborations or exclusive collections that demand a premium look and feel.

The Digitizing Process for 3D Puff Embroidery

At the heart of any quality puff embroidery is precise digitizing. Digitizing is the process of converting a design into a machine-readable file format, and its especially critical for 3D applications.

For custom 3D puff embroidery, the digitizing process includes:

-

Design Analysis: Determining which elements will be puffed and which will remain flat.

-

Foam Thickness Matching: Selecting the appropriate foam height to achieve the desired 3D effect.

-

Stitch Type Customization: Most puff designs require tight satin stitches for coverage and hold.

-

Underlay Consideration: Strategically placed stitches to support the foam and prevent shifting.

-

Clean Edges: Ensuring the top stitches perforate the foam and seal the edges cleanly.

Professionals at True Digitizing handle this process with precision, ensuring seamless application from software to fabric.

Best Practices for 3D Puff Embroidery Designs

While it offers creative freedom, there are a few design considerations for 3D puff embroidery:

-

Stick to bold, block-style fonts or designs with significant thickness.

-

Avoid intricate details or small text, these are best reserved for flat embroidery.

-

Use designs with well-defined edges for cleaner execution.

-

Allow space between puff and flat elements in mixed-designs.

Challenges and How to Overcome Them

Despite its advantages, 3D puff embroidery does come with challenges:

-

Foam Breakage: Low-quality foam can crack or shift during stitching.

-

Machine Calibration: Not all embroidery machines are optimized for puff stitching.

-

Digitizing Complexity: Poorly digitized files can result in misaligned or ragged edges.

By working with an experienced digitizing provider, such as True Digitizing, these challenges can be effectively mitigated.

Future of 3D Puff Embroidery

With increasing demand for personalized, high-quality apparel, 3D puff embroidery continues to evolve. New materials, including eco-friendly foams and advanced threads, are expanding the techniques capabilities. Additionally, hybrid techniques combining puff embroidery with screen printing or heat press graphics are becoming more prevalent.

Conclusion

Custom 3D puff embroidery is more than a stylistic trend, its a long-standing, highly effective method for adding dimension, professionalism, and appeal to textiles. Whether you're a designer, business owner, or creative enthusiast, incorporating puff embroidery into your next project can elevate the outcome both visually and structurally.

For professional-grade results, consider working with expert digitizers who understand the nuance and precision this art form requires. Learn more about how your designs can come to life with custom 3D puff embroidery services by True Digitizing.